Chahakobi Ningyo - Japanese Tea-Serving Automaton

Subject:

The Chahakobi Ningyo is a wooden Japanese automaton from the Edo period, which was designed to entertain guests. Chahakobi Ningyo were a specific type of Karakuri Ningyo (which roughly translates to automaton), whose purpose was to bring a guest a cup of tea, wait until the guest had finished their tea and returned the cup to the plate in its hands, and then return to its starting point [1]. Other Karakuri Ningyo models could fire miniature arrows from a bow or fulfill roles similar to parade floats in festivals, congruent with the rise of entertainment arts during the Edo period [3]. The Chahakobi Ningyo were semi-humanoid wooden dolls, roughly a foot tall, which moved via three wheels connected to a coiled whale-baleen spring, by a complicated gearbox system. Although the interior of the Chahakobi Ningyo most resembled a clock of some kind, they were heavily decorated to resemble a human; all mechanisms were concealed beneath a beautiful miniature kimono, the teacup plate was held in wood-carved human-like hands, and the doll even featured a carved human head which nodded gently as it moved. The doll’s aesthetic demonstrates an Edo-period philosophy which continues to influence Japanese design; “machines do not express their own independent identities but mirror[] human beings” [5]. It constitutes both Japanese and imported Dutch technology, specifically clock making techniques, another trait of the Edo period exemplified within the craft.

Several craftspeople are associated with the creation and legacy of Karakuri Ningyo. First came Hosokawa Hanzo Yorinao, who is best known for creating Karakuri zui (Karakuri Diagram Collection), a book of schematics, written transcriptions, and part diagrams for various models of Karakuri, including the Chahakobi Ningyo. Hosokawa was born at Nankoku-shi, Kochi, in 1949, but lived in both Kyoto and Edo throughout his life. Along with Karakuri, Hosokawa worked on astronomical, navigation, and timekeeping instruments, including contributions (of an unknown nature) to the Kansei calendar [4].

After Hosokawa came Hisashige Tanaka, the son of a tortoiseshell craftsman. He was born in Kurume in 1799, and moved to Kyoto in 1834 to start his machine and inventions shop, where he serviced and sold clocks and other inventions [2]. His work centered around combining Dutch and Japanese technology, clockwork, and Karakuri automata. His works included an automaton that could fire arrows from a bow, and another which could write characters with a brush; both stationary, more complex counterparts to the tea-serving Chahakobi Ningyo [1].

Video: Demonstration of a Chakakobi Ningyo in action.

(https://youtu.be/a2mgv8zmJ1E)

Sources:

My primary source is “Japanese Automata - Karakuri Zui: An Eighteenth Century Japanese Manual of Automatic Mechanical Dolls,” a book by Murakami Kazuo. As the title implies, Kazuo translated two volumes of Hosokawa’s Karakuri Zui and compiled them in his book, along with historical background information and additional information on how to construct certain automata. Given the explicit inclusion of a section on “How to Make a Karakuri Zui Zashiki Karakuri,” I assume that Kazuo wrote “Japanese Automata” to facilitate both analysis and reconstruction of karakuri [4].

As for the original text, Hosokawa’s “Karakuri Ningyo” was the only written documentation of Japanese automata technology in the Edo period, which allowed the wider public to view knowledge otherwise restricted to masters and apprentices of the trade. It was published in three volumes, all after Hosokawa’s passing, documenting four mechanical clocks and nine different Karakuri, which range from the Chahakobi Ningyo and the (relatively simpler, by comparison) stair tumbling doll. Karakuri Zui reads like a set of blueprints, with at least one view of a complete work featuring labeled parts and explanations of how certain sections worked, with additional diagrams of isolated components or sections. However, Karakuri Zui has few explanations for how to physically make each part, implying that either Hosokawa assumed the reader had experience in carpentry and metalworking, or that the book was not intended for recreating a Karakuri, but for admiration and education.

Karakuri Zui has other issues as a reference for recreating an automata; it does not explain how to craft the human features, fake human hair, or miniature kimono that give the Chahakobi Ningyo such a charming appearance. Personally I focused on the mechanical aspect, having neither the time nor experience to worry much about those features; however, I suspect that the techniques employed to create the Kyo dolls of the Edo period were reapplied to Karakuri, as the two bear similar appearances, garb, size, and art style [7]. Another, more pressing issue is that most, but not all components have measurements. This caveat is perhaps the most significant evidence indicating that Karakuri Zui was not intended to teach the reader how to make automata, because the mechanisms would not work correctly if they did not fit together, and in order to replicate the correct fit, a reader would have to know all measurements. Additionally, in their analysis of early modern Japanese technology, Erich Pauer and Ruselle Meade note that “at least one drawing is not correct,” and argue that without the unwritten intellectual resources of Edo period craftsmen, such as fellow living experts and observation of completed models, “it was not possible to reconstruct [a Chahakobi Ningyo] with only Karakuri Zui [6]. Deriving quantitative relationships from the drawings was the most significant challenge in my recreation, which required educated assumptions and experimentation, informed by critical thinking and some previous engineering experience.

Note: for copyright purposes, I am not able to publish photos of the diagrams or contents of Japanese Automata.

Reconstruction:

Is it possible to apply modern engineering tools to premodern mechanical devices? What are the advantages and disadvantages of doing so?

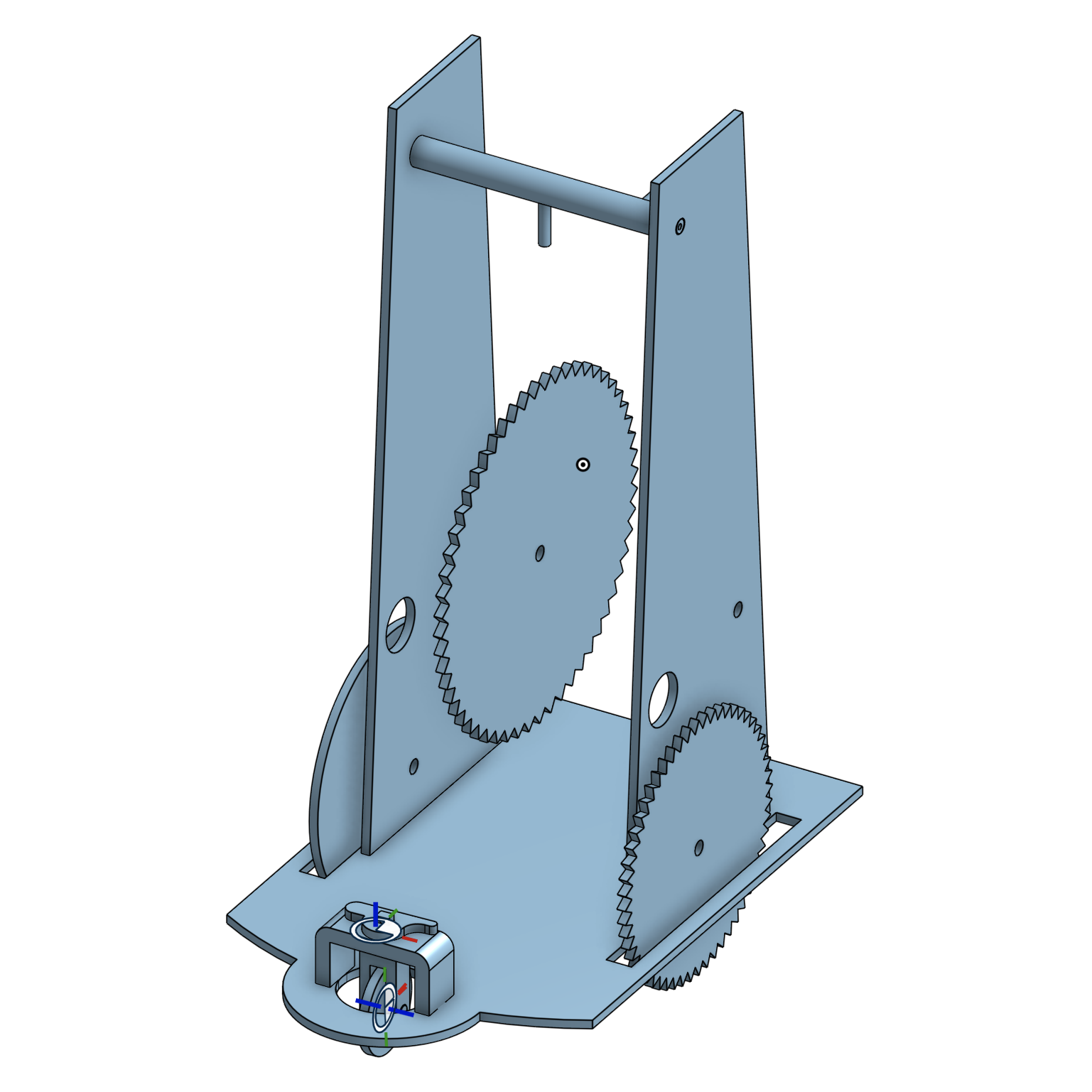

To address this question, I decided to attempt to remake a Chahakobi Ningyo tea-carrying automata, using CAD (Computer Aided Design) software, 3D printing, and laser cutting. This was also to play to my skills as an engineering undergrad with minimal carpentry and metalsmithing skills, and to facilitate prototyping and time efficiency. Laser cutting allows for the quick, precise fabrication of two-dimensional wooden parts, just like the gears and plates of the Chahakobi Ningyo, making it an ideal compromise of traditional materials and modern engineering. Although I was not able to in the end, I could have purchased oak and cherry wood, two types of wood listed by Kazuo to have been traditionally used. While laser cutting is somewhat limited to two dimensions, 3D printing is not, which facilitates making more complicated parts such as the mounts for the sakigake-guruma (rotation/pivoting mechanism), an otherwise tedious task for a sub-amateur carpenter. As for designing the parts to fabricate, CAD allowed me to easily edit and model components and mechanisms, essentially acting as a dynamic, three-dimensional sketchbook which could translate almost directly to the laser cutter or 3D printer.

Reading Diagrams:

I started by simply reading through the section of “Japanese Automata'' on Chahakobi Ningyo, to get some sense of the physical relationships and diagrams, which were hard to understand at times. Personally, having a mental image of the device was just as important as having a sketch, 3D modeled or otherwise. Given that Karakuri Zui contains the only known illustrations of Karakuri, I figured that Edo craftspeople had to rely on their mental image as well, along with the expertise and work of other mechanics.

Even with multiple views of the gearbox and written explanations of each mechanism's premise, it took time to figure out which parts were connected, which were not, and how they interacted. The most confusing part remains how a wooden automaton, with no computational systems, could perform such a complex sequence of actions; in other words, how it “knew” to turn around after a certain distance, but otherwise travel straight.

Measurements

Next, I went through each page and recorded every measurement, along with the page it was from and what component it described. Interpreting the diagrams was difficult here as well, because only some measurements had lines indicating which specific part they referred to, or how far a measurement encompassed. For instance, the “whole length” of the base plate is stated to be 5 sun, 5 bu, which translates to about 16 cm, or 6.5 inches. However, this measurement came from a translated written description, not a diagram label, and I was not sure whether this referred to the base plate’s straight length only, or the total length from back to curved front.

To resolve this, I assumed the latter case and modeled the base plate in OnShape, the browser-based CAD software of my preference, to see how it looked. The proportions seemed noticeably shortened compared to the diagram, and there did not seem to be enough space to fit the mechanisms, so I edited the model so that only the straight lengths of the base plate were 16cm. This produced a plate which looked much more like the original diagram, so I stuck with that. There were other instances in which I had to eyeball a measurement or position to fill in gaps, such as the linear position of the axle holes of the baseplates; Karakuri Zui listed their height relative to the bottom of the plate, but not their horizontal placement, so I had to guess based on the diagrams; later on, I was able to shift the holes for the wheel axle based on the diameter of the wheels and the wheel cavities in the base plate, but that was still an educated guess based on the illustrations.

As was briefly mentioned above, all measurements in “Japanese Automata” were translated from “Karakuri Zui,” and used the shakkanhō Japanese unit system. Using a military handbook, I converted the shakkanhō to feet and inches for visualization, and millimeters for modeling. During this process, I noticed that all three wheels had a thickness of one bu, or roughly 3mm. Conveniently, that was also the thickness of the most-available wood sheets at the Spartan Makerspace, which housed the fabrication equipment I needed, so I decided to make the standard thickness of all parts 3mm, unless they were obviously different in the diagrams.

Modeling

I began modeling parts in OnShape, starting with the base plate and a side plate. As the “foundations” of the Chahakobi Ningyo, and as parts shown from multiple angles (including looking directly at their surfaces) in the various diagrams, these made the most logical sense to start with. A common strategy I developed was starting from the outside and working inwards; modeling parts with more clearly defined measurements or a more structural role in the Karakuri, and using that “frame” to infer the modeling and arrangement of comparatively smaller parts with fewer measurements.

Another useful trick was to make a cardboard cutout mockup of a part, using the measurements, to get a tangible sense of scale. Due to time, I only made a mockup of the base plate and one of the cogs, but with it I was able to infer measurements for the wheel slots (which were not given) and make sure the hole for the sakigake-guruma was the right size.

Fabrication and Assembly

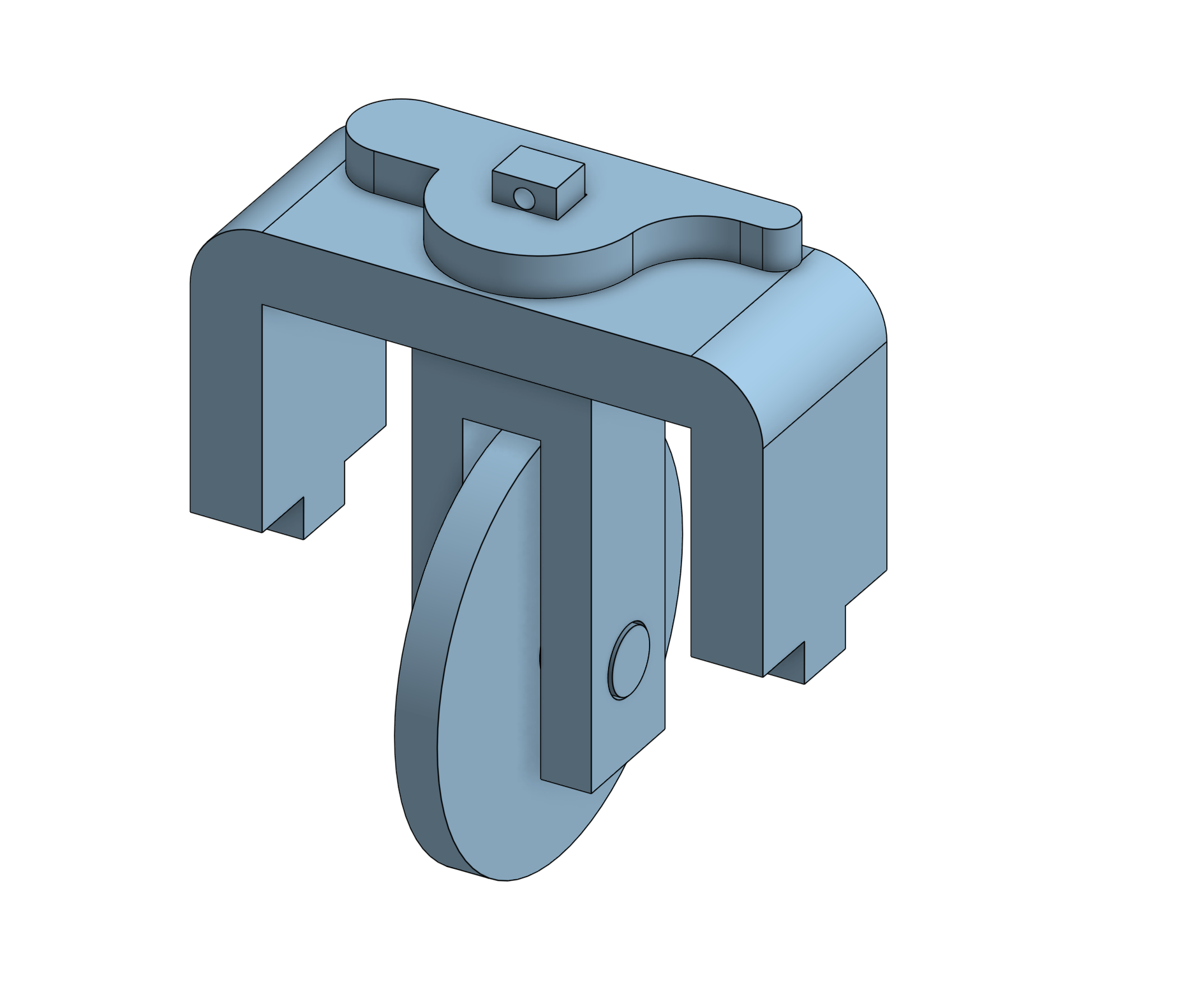

After modeling each part individually came the process of putting them together digitally as an “assembly,” essentially reconstructing a digital model of the Chahakobi Ningyo itself. This was to ensure that all pieces fit together properly and account for how certain parts moved. For example, I made a subassembly for the Sakigake-gurama, the pivoting wheel at the front of the base which controls direction, and applied different types of “mates,” constraints between two parts which determine how they move in relation to each other, so that the wheel could turn and pivot.

Karakuri Zui dedicated four pages to the Sakigake-gurama and its individual components, which made them much easier to model, and given how many small parts the mechanism contains, it made sense to make a sub-assembly.

Finally, once all parts appeared to fit correctly, I exported to the 3D printer and laser cutter to fabricate the parts in batches, and put them together. Kazuo’s guide on how to make a Chahakobi Ningyo said to use bamboo or oak for the pins connecting each part; unfortunately I did not have time to make the equivalent of wooden nails, and had to use hot glue. In many cases, I had to expand connection holes/slots with a file, but this was more a result of my own underestimations and lack of explicit instructions for some hole diameters. I used a diameter of 5mm for most axle holes, since the dowels I had to use for all axles were the same, but had to expand the holes with a file to make enough clearance to rotate.

Reflection

In some ways, my reconstruction is historically accurate, although in others it could be improved. It uses the same type of materials (as appropriate, given the question), and follows as closely as possible to the source material from Karakuri Zui. However, some materials could have been more accurate, and most pressingly, my reconstruction is incomplete.

There are many, many ways in which my reconstruction could be improved. Had I used the time available more efficiently, I would have been able to complete much more of the mechanical systems, or at least have some functionality, and could have also used more traditional materials such as cherry or oak wood, as I had originally intended. For deciphering the complex gearbox, another scholar could take time studying the clock schematics in Karakuri Zui, as clockwork was the field from which these automata descend [6]. Using time more efficiently and starting earlier would also allow a scholar to fabricate multiple prototypes, either of the full automaton or of individual components, which would refine the final product.

Regardless of completion, other takeaways from working on the Chahakobi were still insightful. The source material gave me some insight into how Edo craftspeople might have inferred some measurements or proportions based on the illustrations of Karakuri Zui, without having to rely on labels (for example, the base plate length). Quantifiable measurements could also be extrapolated by doing some simple arithmetic with known measurements, or combining known measurements with some reasoning based on the end result;

For one of the axles running horizontally through the body, I extrapolated a length by adding up the width of the gearbox, the cavity for the mainspring, and an additional bu (≈3mm) to be sure.

For the mainspring cavity’s width, I assumed it must be roughly 6 bu (≈18mm) because the spring itself is only 5 bu (15mm). But if the cavity were the exact width, the spring would scrape against the sides and produce excessive noise, so I assumed an extra bu to give the spring more clearance. Because I could not finish my reconstruction, I do not know whether this measure was necessary, but from an engineering perspective it made sense.

Based on this reconstruction, I believe that it is possible to apply modern engineering to early modern technology. It requires a great deal of time for experimentation and detailed analysis of source material, but the ease of fabrication using modern tools can make the process significantly easier than using hand tools.

Bibliography

Boyle, Kirsty. “Karakuri Ningyo.” Karakuri.info, 14 Jan. 2008, http://www.karakuri.info/index.html.

Hashimoto, Takehiko. “Making and Using Scientific Instruments in Japan: How Scholars and Craftsmen Cooperated, 1781–1853,” Technology & Culture 62.2 (2021), p 414.

Holcombe, Charles. A History of East Asia: From the Origins of Civilization to the Twenty-First Century (Cambridge: Cambridge University Press, 2011), “Early Modern East Asia (Sixteenth–Eighteenth Centuries),” p 193-195.

Hosokawa Hanzō. Japanese Automata: Karakuri Zui: An Eighteenth Century Japanese Manual of Automatic Mechanical Devices. Translated by Kazuo Murakami, Murakamikazuo, 2012, p 102-125, p 10, p 247-248.

Kurokawa Kishō. The Philosophy of Symbiosis. Academy Editions, 1994, p 183.

Pauer, Erich, and Russelle Meade. Technical Knowledge in Early Modern Japan. Renaissance Books, 2020. p 49, 51.

“京人形: 京都の伝統工芸一覧.” 京都伝統工芸協議会 京都の伝統工芸 "Kyo Doll," Kyoto Traditional Crafts Council, http://www.kougei-kyoto.jp/kougei/ningyo.html.

Measurements:

Isby, David C. “Appendix.” Handbook on Japanese Military Forces, Louisiana State University Press, Baton Rouge, 1995, p. 400.